Articles

Vision

The problem with Vision is spelled out in my previous article, Vision Quest, Part 1: What You Get is Rarely What You Need. I wrote, “Most Visions (are) nothing more than a meaningless poster on the wall!” Until the problem is recognized, identified, and owned, nothing ever changes.

We discussed the first key element required to address this problem in Vision Quest, Part 2: How to get What You Really Need, which stated, “The first foundational principle that supports all effective and robust Visions is ‘Reality Trumps Fantasy.’ Fixing the problem begins with having a clear understanding of reality. It is difficult to make happen, but it is not rocket science!

The second key element necessary for the creation of a powerful and effective Vision: Serial Vision. Simply put, way too much attention is paid to the end and not enough to the steps that get you there!

In this column, we are ready to discuss the second key element necessary for the creation of a powerful and effective Vision: Serial Vision. Simply put, way too much attention is paid to the end and not enough to the steps that get you there.

Ending the End-State Obsession

Whether by chance or intent, Visioning efforts not only look at what the end state goal ought to be—they obsess about it! This obsession results in an absolute, permanent and unchanging Vision/Vision Statements. Everyone will say the statement is dynamic, but in real life it is static. In the leaders’ minds, the visioning effort leads to the thought, “now we have it, we know where are going.” Unfortunately, such a belief is a terrible misread.

People do not behave, think, live or work in this kind of a mindset. Hit the pause button for a second to reflect: Can YOU keep in mind what the organizational world is supposed to be in five years? Can YOU keep in mind what this means for you or your team or your direct reports or your supervisor? Most of us are fortunate if we can remember, in an applied sense, what our yearly goals are.

I know I cannot stay connected to the end-state, “poster on the wall” fantasy. I know that it is not just a stretch goal, but that (unfortunately) it is an all too often impossible and implausible goal! Perhaps the inhabitants of the Executive suite can stay plugged in, but rarely can anyone else. But wait a second—what is the purpose of a Vision? It is to grab the attention of the people who are making it happen, on the shop floor—day-to-day and 24/7.

This is not a criticism of executives or leadership; but Vision is intended to be aspirational and create hope in the workforce. How can that happen if attaining the Vision is just not possible?

There are visionaries who can spend their days in big picture abstractions. Such individuals are out there. As a matter of fact, this is a core trait of a transformational leader. However, transformational leaders are basically mythical creatures; you are more likely to be struck by lightning than you are to find and work with a truly transformational leader. Their ability to create, drive, and achieve “big picture” pictures is very rare.

Serial Vision creates a chain of unbreakable but attainable links.

This problem, however, can be fixed, even without a mythical transformational leader. Visioning needs to be looked at as an iterative process. First, identify the stretch goals that will drive the organization to make major and significant leaps toward the future state. These are achievable leaps, even those that sometimes require ineffable leaps of logic. Then sequence these Visions. Serial Vision creates a chain of unbreakable and attainable links. Serial Vision will take you to the future state that is not just a poster on the wall.

Leveling Up

I reflect again on my equestrian passion to explain. My personal riding Vision is to compete and be competitive in dressage. There are 10 levels of dressage tests: three in Introductory, three in Intermediate, and four in FEI (Federation Equestrian International). Simply getting your horse to move gracefully in a circle is very difficult; what FEI-level riders do is amazingly difficult. I passionately want to become good enough to compete in the Intermediate levels. Even this is perhaps unattainable in the years that I have left to ride. It is a stretch dream, a “big-leap” Vision!

To aspire to compete at the highest FEI Level, Grand Prix, is just plain foolish and counterproductive. While it is a huge stretch goal to compete at the Intermediate level, it is drug-induced fantasy to compete at the higher FEI level. Making that my goal will get in the way, not get me there.

Recent news out of Tesla provide a current, real life example. The company set a goal—a Vision—of 5,000 units per week. It has not been reached (not even close.) Neal E. Boudette, in an April 16, 2018 New York Times article, states:

“In production of the Model 3, Mr. Musk gambled by creating an assembly line that relies much more heavily on automated equipment and robots than workers. But it has proved more difficult than he expected to get the machinery to work in harmony… he has described the delays and glitches as ‘production hell.’

“In a tweet over the weekend, Mr. Musk acknowledged that ‘excessive automation at Tesla was a mistake. To be precise, my mistake. Humans are underrated.’”

Attainable, Achievable Process

A Vision of an automated plant where the product is rarely touched by human hands is a meaningless poster on the wall. Now the Tesla workforce is paying the price. I bet you big money at long odds that the workforce knew this was an unattainable, foolish, and perhaps reckless Vision. Not that it can never be achieved—but that it almost certainly cannot be achieved in the necessary time frame, with the available resources and current technology. Get ahead of yourself at your own peril.

In paper manufacturing there is a Vision of a world where no lift trucks and no humans will touch the paper once it comes off the reel until it is shipped out on rail or truck. As a dream this is interesting. As an attainable Vision for most mills it is off the chart crazy.

Most mills cannot get housekeeping right. The metrics are reviewed religiously. Housekeeping has a direct impact on safety, productivity, maintenance costs, mean time between failures, and basically everything that is important in a profitable facility. Yet keeping housekeeping at the Vision state is usually an elusive and never achieved state!

A shop floor where a new coat of light-colored paint stays clean for months is a major step. A floor where any oil leaks or metal shavings are instantly recognizable is a tremendous step forward. These examples might be links in a Paper Manufacturing Serial Vision process.

Serial Vision requires that teams revisit frequently where they are and retool again and again to get to where they want to be.

Thinking about Vision as a serial process forces attention towards the process. Vision is a series of short-term plans/accomplishments. Serial Vision requires that teams revisit frequently and effectively where they are and retool again and again to get to where they want to be.

An important hidden benefit is that the workforce will believe you have some smarts and “common sense.” They will believe that you listened to them up front, which is highly unusual, and that you continue to value and listen to their ideas going forward. My goodness: this is employee engagement in practice, in real time, in the real world!

Vision is not one and done.

Vision is not “one and done.” It requires an initial commitment of time and energy. Even more importantly, it requires a serial commitment of time and energy. Three to six months is the limit of

Vision for most of us. At the end of this time cycle the process must refresh. It is not as difficult as the initial Vision setting, but it is perhaps even more important.

It is the course corrections along the way that will align the organization to an attainable, achievable and viable future. Serial Vision, Iterative Vision, Renewable Vision: it works, because that is how “we” work.

My previous column, Vision Quest: What You Get is Rarely What You Need includes the following thoughts:

“The core problem is relatively simple and probably obvious… Every organization puts these things together, but too often no one outside of the ‘must-know’ crowd can remember what the heck the words are, let alone what they mean. They are just another meaningless poster on the wall…

“Why do we spend so much time, energy, and resources on efforts that no one remembers? Because clearly, when it works it has an amazing impact. Equally clear is that it does not work very often. The real question is how do you get what you need? How is a Vision crafted and made real and alive? How do you make sure it is not just another forgettable slogan?”

What companies put out there as Visions are such end state, drug induced fantasies that the people in the organization quickly know it is just a bunch of malarkey.

The first foundational principle that supports any and all effective and robust Visions is really simple. That principle is Reality Trumps Fantasy. Every time! What companies put out there as Visions are such end state, drug-induced fantasies that the people in the organization quickly know it is just a bunch of malarkey. Huge amounts of time are spent daydreaming about what the heck the facility will look like in five or ten years, when it is inconceivable that the organization could get there in 25 years.

There is an unspoken, unanalyzed mindset that Visions are intended to be perfect reflections of achievable end state fantasies: “We will become an ownership-based work system, yet our present environment is one of employee/management internecine warfare, using unreliable and undercapitalized equipment, staffed by uncaring and unmotivated employees, led by command and control freaks, where everyone is pulling their oars in countless different directions.” Somehow a magic wand is waved, the silver bullet is found and voila, a self-actualized team environment is created—usually in a few months!

In one major capital project in the paper industry, part of the Vision for a new product system was that

no human being would touch the paper once it left the end of the paper machine until it was driven away from the loading docks. In a paper mill this is a long way to travel. The route from a paper machine to converting department to loading docks is complicated and dangerous. The automated handling systems must navigate multiple intersections, doors, pedestrian cross walks, and all sorts of other obstacles.

This organization’s Vision also included the idea that there would never be a lift truck operating in the Converting Department! If you are familiar with heavy manufacturing/continuous process operations, you know that the hourly workforce viewed “no lift trucks on the converting floor” as the dream of very naïve, and very foolish, salaried employees. It is a great dream, but not one that was ever achievable in the available time frame. It took more than 18 months just to get the automatic transfer equipment to work as intended.

The first day paper was made, lift trucks were required. Lift trucks were required to transport and stage paper rolls, and to load converted product onto the trucks and rail cars to be shipped. The operators were laughing and crying; the mechanics were laughing and crying. Operators and mechanics knew that the stated Vision would not—could not—work. Nevertheless, the workforce had to live with the consequences of a Vision that over-reached terribly. They paid the price of brutal hours, brutal working conditions, and brutal reality. Everyone that worked on the floor was saying “I told you so.” This Vision was not aspirational, uplifting, or motivating. It was the exact opposite. It crushed hope, destroyed trust, and made people bitter and suspicious!

Visions are not small teeny steps, nor easy to achieve. They are by their very nature – bold!

This is not to say that “no human beings and no lift trucks” was not the place that this organization needed to get to. It is critically important to set stretch goals, big leaps. Visions are not small teeny steps, nor easy to achieve. They are, by their very nature, bold! Hand-in-hand with bold leaps goes turmoil and chaos. Almost always, bold Vision requires working in concert with other employees in profoundly different ways. Often it means adding and modifying job responsibilities so that they become unrecognizable compared to current state.

Finding the Critical Intersection

The critical question is how to get there, and if the “there” is unbelievable, you are doomed to fail. Guaranteed! My advice is to confront, in a brutally honest way, current reality. Start from what is. Do not talk about creating a transformational change endeavor that reaches such a glorious Vision that the Harvard Business School will want to write it up as a case study.

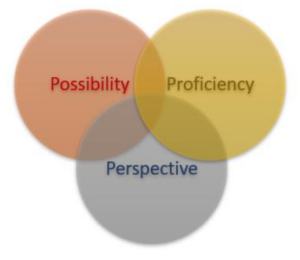

Vision is the Venn diagram intersection of Proficiency, Possibility and Perspective.

Simply put, Vision is the Venn diagram intersection of Proficiency, Possibility and Perspective.1

Possibility is focused on leverage points, often linked to projected major change initiatives. Is there an upcoming capital project? Is there a new product launch or modification? Perhaps a facility-wide operator skills training initiative is planned. There are a host of opportunities.

Proficiency is focused on the skill of the workforce. Is the workforce capable of performing maintenance tasks, change overs? Are they able to flow to work? Are they qualified in multiple tasks and jobs? Are they self-directed? Do leaders empower and inspire?

Perspective is focused on the business outlook. What is the competitive landscape? What is the risk reward analysis? Is there time to experiment, or is doom on the horizon?

Vision comes from where all three intersect. As is shown in the diagram, this is a very small subset of the total set of options – a very small subset. If the organization has no upcoming major capital projects (Possibility) and is perfectly happy with the current state (Perspective), then acting on a Vision that requires everything to be turned upside down and inside out (Possibility) is probably a non-starter.

If you are staring shutdowns and curtailments in the face (Perspective), then the Vision may be as simple as doing what is necessary to survive; economic crisis eliminates many options and opens up others. You cannot have flow to work (Proficiency/Possibility) if operators are not qualified at executing multiple tasks, in multiple jobs (Proficiency), as needed. You cannot reasonably expect a workforce that has never been responsible and accountable (Possibility/Proficiency) for much of anything to become self-directed (Possibility) in a few months. It just will not happen.

For some reason, Proficiency is often the most difficult of the three elements to evaluate and accept. Leadership’s inability to realistically judge organizational effectiveness and skill continues to stun and amaze me. Either that, or the shiny gold ring of creating a “high-performance work team” or an “ownership-based work system” overwhelms practical thought and action. Most leaders believe

there is a competitive advantage to ownership-based systems. Most leaders want it in their business. However, having the Vision of high performance and doing the work necessary to get high performance are two very, very different things.

Do not get hung up on precise definitions of these three terms. They are intended to be a guide. They are intended to help one think about what a creative, stretch and attainable Vision might be. All three are critical; Vision is the intersection of all three elements, not just one or two.

Reality Trumps Fantasy. Apply this principle in the framework of the three element Venn diagram and you will be on the right track. It works!

Reality Trumps Fantasy. Apply this principle in the framework of the three-element Venn diagram and you will be on the right track. It works!

1 10-plus years ago, while a member of a Koch Industries Market Based Management team, I saw a version of this Venn diagram centered on a free market perspective, using free market language. I have never come across anything like it in a classroom setting or in print since that time. I believe I have made this model more powerful, simpler, and more useable.

Have you ever been a part of a visioning exercise? If the answer is yes, then raise your hand. I am sure a whole bunch of hands went up. If you have been part of an organization, work system, or department for longer than a year the real answer to this question is—everyone. Why is this done? What is the reason?

The answer is to make sure we avoid the Abilene Paradox1, where everyone agrees to go somewhere when actually no one wants to go there at all; or the insanity of a boat where half of the occupants’ paddle one way and half the other. It is a foundational approach to gaining alignment, to come to an agreement on where we are going, to make sure we are all on the same page. If you do not know where you are going, then how can you possibly get there? Right? Right.

If you do not know where you are going, then how can you possibly get there? Right? Right.

So, everyone’s hands are now up in the air. The next question is: what did the process of building a Vision look like? Did you imagine what your facility or department would look like in five years?

For instance:

Safety: no lost time accidents, no recordable injuries, no first aids… Reliability: best in class uptime and runability…

Workforce: highly motivated, skilled and qualified operator owners…

Does this sound familiar? There would also be a discussion about, or a road trip to, recognized world-class organizations. What are their Visions like? How did they make them real and alive? Toyota, Procter & Gamble, and Google might have been high on the list.

Toyota has been the gold standard in the manufacturing world for a long time. The Toyota Way/Lean Manufacturing has been a force, so much so it seems that every continuous process manufacturer in the United States has tried at one time or another to emulate Toyota. So, often Vision teams say, “let’s go to the Toyota Georgetown plant and see how it is done.”

P&G is also high on the benchmark list. The story line about P&G is that the words are real, and everyone knows and understands them. The Vision is not an exercise, but the way that people act and think and make decisions every day. It is the North Star of who and what the entire company is all about. The Vision is real!!

The Vision is not an exercise, but the way that people act and think and make decisions every day.

It is interesting to remember that General Electric, Kodak, and Saturn used to be on this list, but not anymore. General Electric was (and perhaps will be again) a best-in-class company. They used to be the largest US industrial company by market value. Boeing now holds that position. Right now, GE must rediscover and retool what works. Jack Welch’s vision no longer fits, and Jeff Immelt is no longer the

CEO. The company is a shell of what it used to be.

Kodak’s vision during its heyday was formulated and driven by George Eastman.

He did not have a degree in Chemical Engineering, but his approach to film was

that of a chemical engineer. This mindset helped to create one of the most

successful companies in American history. Kodak made photography

inexpensive and easily accessible to everyone. All well and good until the world of digital photography arrived, with a vengeance.

In a manufacturing environment, if you are cutting edge you might have hourly operators and salaried leadership working together to create the Vision. They would be equal partners. The result, when done right, is joint ownership and tremendous buy-in. This is how it used to be at Saturn. In its heyday, the storyline was that Saturn had turned visiting its organization into a profit center, never laid employees off, had a very identifiable brand, and sold a large number of well-made vehicles. They are no longer in existence.

When a Vision Works

Out of all this effort comes a Vision statement. A Vision statement describes a picture of what the company, division or department will be. This statement captures that essence. In a short and concise phrase or a sentence or two, the future state is laid out there. It is easily remembered and has an emotional appeal to all members of the team, the department, or the entire company. Ford’s “Quality is Job 1,” Nike’s “Just Do It,” the Army’s “Be All You Can Be,” and Facebook’s “Get Members” all are examples of pithy and powerful statements. They are memorable and remembered.

A Vision statement can also be loaded with ideas like beating all future competitors, being first or second in a business segment, having world class uptime and efficiencies, deploying capital more effectively than anyone else, or being world-class comparative to internal competitors and, even more importantly, to external competitors! Length and complexity, however, are both red flags. Very quickly the statement is no better than a computer-generated algorithm of buzzwords and jibber jabber.

Very quickly the Vision statement is no better than a computer- generated algorithm of buzz words and jibber jabber.

Successful Visions are aspirational as well as directional. A Vision is intended to capture the hearts as well as the minds of the organization. Everyone must row in the same direction, in unison, at the right time. Leadership schedules a series of communication meetings. A banner or two is put up and everyone signs it. Wallet cards are printed, and T-shirts are handed out. The new Vision is rolled out. Hurrah!

Heartfelt congratulations to everyone who has participated in and tried to make real such efforts. It is the right thing to do. However, in reality; the whole Vision thing is messed up.

The core problem is relatively simple and probably obvious. To everyone who raised a hand: without looking at a wall poster, a wallet card, or asking your nearest colleague, what is the Vision statement? Every organization puts these things together, but too often no one outside of the “must-know” crowd can remember what the heck the words are, let alone what they mean. They are just another meaningless poster on the wall.

Every organization puts these things together, but mostly no one outside of the must know crowd, can ever remember what the heck the words are, let alone what they mean.

There must be a better way. Vision is critically important, essential and necessary! I have been a part of two organizations in my professional lifetime that were non-traditional, high-performing, ownership-based… call it what you want. Work at these organizations was not a four-letter nasty word, but rather an inspirational gift. I really did not understand at the time what a gift it was to work with a group of people that cared, gave a damn, and were committed and dedicated to living the dream. It was electric. It was successful.

These organizations were competitive and enduring. They beat the socks off any internal comparative operation and were better than almost every comparable external facility (not all, but almost all!) I would go back if I could. I wish I had appreciated better at the time what I had. These experiences are alive in my heart and mind. They guide my actions with regards to every subsequent effort to create a High-Performing Work Team. I have a personal/professional vision of Ownership-Based Work systems.

Why do we spend so much time, energy, and resources on efforts that no one remembers? Because clearly, when it works it has an amazing impact. Equally clear is that it does not work very often. The real question is how do you get what you need? How is a Vision crafted and made real and alive? How do you make sure it is not just another forgettable slogan?

In follow on articles I will speak to what works better. Please stay tuned.

1 The Abilene Paradox: Harvey, J. B. (1974). “The Abilene paradox: the management of agreement”. Organizational Dynamics. 3: 63–80: In the Abilene paradox, a group of people collectively decide on a course of action that is counter to the preferences of many or all of the individuals in the group.”

Leadership

Let me be clear – manufacturing of the future defined as a manager and his dog is a false path, a path that screams failure.

This article is intentionally provocative. It turns upside down the quote from Warren Bennis about the factory of the future. I wrote it thanks to the auspices of Stephan Whitley, who among other things is one of the founders of Caravel Solutions, LLC. I hope it will spark readers to think about an alternative approach to the workplace and workforce of the future. —EC

People are the only ones who can change the game, change the rules, break the rules, i.e. innovate!

Let me be clear – manufacturing of the future defined as a manager and his dog is a false path, a path that screams failure. If you have the courage to see what is in front of your eyes, then you know this is a one- way ticket to mediocrity at best and failure at worst. This path permits you to stay in the game, but it prohibits you from excelling at the game. A manager and his dog mental model make it impossible to adapt, improvise, or improve. This mental model makes it impossible to change the way the game is played. People are the only ones who can change the game, change the rules, break the rules, i.e. innovate!

New equipment, new controls, new automation provide a feeling of security, a sense that we are staying ahead of our competitors. This is a dangerously false sense of security because the reality is there is no such security. The reality is that with the necessary capital, any equity group, any company, any individual can purchase the same equipment, the same automation, and the same distributed controls. All that is required is money. New technology is a momentary advantage. This is known by everyone and is written and spoken about ad nauseum, but unfortunately is almost immediately forgotten. With incredible speed the competitive advantage is shredded by the next newest purchaser of not the same equipment, but better next generation equipment with all sorts of updates, upgrades, and bells and whistles. All well and good except that doing all of the standard, necessary normal action plan things will not paint the picture needed for success. What is required is an absolutely crystal-clear picture of what is realistically possible, feasible, attainable and sustainable.

Capital is the life blood of any manufacturer. Without it you are on a death spiral. With capital you are just barely staying ahead of the ravenous pack of competitors who are constantly nipping at your heels.

Let me be equally clear – continuous improvement in all forms of automation and use of data analytics is absolutely a necessary part of the future of United States manufacturing. It is reported periodically that American manufacturing is dying. This is not true. In many industries like steel, production volume is the same or greater now than it was in the heydays of the 70’s when the USW union boasted 300,000

members. What has changed is the number of operators and mechanics required to produce this volume. These numbers have shrunk more than 60%. This is the right thing to do. The competitive global landscape requires such drastic changes. Do more with less.

What is absolutely delusional is to believe that automation will get you to the Promised Land. The hidden core premise of technological improvements is to “idiot proof” the operations. This concept is the dark side of technically minded, exceptionally bright, and degreed leaders. It is a mindset based on the belief that engineering can fix anything. This strategy is put together by technically gifted people, surrounded by technically competent people, surrounded by technical marvels such as paper, glass, and steel fabrication machines. Foundationally it assumes that intelligent machines add more value than creative human beings.

Even worse is another hidden assumption which is that people are the problem. Control systems work but the people do not. If intelligent machines add more value than creative people, then people are the problem. Human beings need to be worked around. They get in the way of improvement. They have nothing to do with a solution and are in fact the problem. At best they can monitor a control panel, and God forbid they ever get in a position where they must make a judgement call. The best bet is to “idiot proof” the operation because the operators are idiots.

Operators… Treat them like blunt, broken tools and you will be rewarded with blunt, broken tool behavior.

What idiot proofing the operations really does is to create idiots! This is a truly lethal self-fulfilling prophecy. Operators have the potential to be the competitive advantage. They have the capability to be inventive, ingenious, and creative when it comes to running the operation. It is a given they are geniuses when it comes to seeing through the hidden assumptions’ smokescreen. They know when they are perceived as idiots. They know when they are seen as the problem. They know when they are sacrificed on the altar of technology. Treat them like blunt, broken tools and you will be rewarded with blunt, broken tool behavior. If you have operators that are waiting for “you” to tell them what to do, then you are living with the organizational consequences of believing that intelligent machines can outperform creative human beings.

This strategy is a tacit admission of a complete inability to lead people, to guide people, to believe in people. It is a belief that you can only minimize the negative impact of the human element. It assumes people cannot be led, disciplined, encouraged or do more than stay out of the way. It assumes they cannot create value and, more often than not, destroy value. It belies completely the catch call phrase of the past 30 years that “people are the most important resource”!

It is an overt admission that as leaders we have failed to discharge our most basic responsibilities. Leaders cannot lead let alone manage their workforce. We do not hold people accountable. We do not provide direct consequences for poor performance and are even worse at providing incentives that recognize

superior performance. We want perfect employees doing what is in the best interest of the business, every day, every shift, every hour, with every decision.

Human Resources is supposed to hire these mythical creatures. Every hire is to be such a person. There are self-directed, self-actualized individuals in every operation. They are the go-to folks, the ones that are asked to fix things, run things, optimize things. They are the next front-line supervisors and maintenance planners. If they are not that good, then Human Resources made a mistake, and if they just would get it right everything else would be all right.

Organizations say that mistakes are a part of growth, but the reality is that we expect perfect analysis, perfect decisions, perfect execution and perfect outcomes, every time! If “they” cannot be perfect, then we want automation to replace “them” because dealing with “them” is just too difficult and too frustrating! They are just a pain in the backside. They do not stay fixed.

In other words, we wish they were just like a machine, without ever realizing or acknowledging that machines always break down as well. It is okay for machines to fail, but not okay for people to make mistakes! There is no belief whatsoever that people really are the competitive advantage.

Actual operators and front-line supervisors, and mechanics and electricians and instrument technicians know they are regularly seen as an unavoidable problem. They may not like seeing their numbers dwindle, but they get it. They get it that more loops and controls and analytics make for a more efficient operation. What they cannot stomach is a bunch of bull about how they are the most important asset when every observable data point confirms they are only there until a smart machine can replace them.

…people really are the competitive advantage. …they are dog gone great.

The true competitive advantage, the surest path to value creation is creative human beings. People are the most important resource. Instead of paying lip service to this catch phrase, we need to believe it and act on it in a meaningful way. We need to viscerally get it that people are inherently interested in doing their best. Leaders must tap into this resource, not marginalize it, or run away from it. Anyone who has been privileged enough to work in an ownership-based system knows such a facility can compete successfully with outdated equipment, undercapitalized assets and almost any other negative imaginable.

Operator ownership means that I give a damn. When the workforce gives a damn, they are not only dog gone good, they are dog gone great.

Efforts to evaluate, in an absolute sense, organizational change initiatives focus on quantitative metrics. A hard number states unequivocally that targets are exceeded, met or not met, relative to a specific time period. Engineers and financial professionals are especially enamored of this approach. Metrics are comfortable, convenient, and necessary, and do not even come close to effectively grading the value of any given change initiative.

After 35 years of working on organizational change initiatives, ranging from pilot approaches to full site transformations, that ran the gamut from vertical start up curves to phased startups, linked to equipment specifications and operating parameters, I rank such comfortable metrics as no better than a distant second choice. These numbers, good or bad, give only an initial impression, and miss by a wide margin getting at what is really important.

The real metric lies in the Three Leader Litmus Test©.

Capital projects, improvement projects, work redesigns or reorganizations are all inherently cultural change initiatives. Getting a group of people to do something in a different way, in concert with different people, often across siloed boundaries, with different equipment, in a different sequence for different/better results requires massive cultural change. Companies often say: “people are our most important asset”. This may be the case, but people are also emotional, opinionated and hard headed. They are not machines, do not behave like machines, and never will. Until there are no human beings in the workplace, change will always be chaotic and messy.

Until there are no human beings in the workplace, change will always be chaotic and messy.

I recently attended a meeting to discuss the factory of the future. It was a three-hour session. Within the first 15 minutes the speaker emphasized the human issues in such a factory. The next 23⁄4 hours were spent talking about Distributed Control Systems, Artificial Intelligence, remotely controlled operations, and never again were the people a part of the equation. People, and the teams they are a part of, are so difficult to create and adapt and lead, it is simpler to note this reality and move on to the technology. This is exactly what happens in real life projects.

So, let’s talk about the Three Leader Litmus Test©.

The first leader is the Initiating Leader. If the project has any chance of success, it is because this individual is strong enough to shield the impacted organization from the insanities, stupidities, and vicissitudes that are legion in any major project. Assuming this leader is strong enough, and such strength and skill is very rare indeed, your project will likely survive first contact with the real world.

A Vision will be laid out that is believable and compelling. The Leader’s Vision will be strong enough to break through the nearly impenetrable road block of the flavor of the month disease. A plan will be crafted that addresses critical skill gaps and makes the workforce believe that just maybe this time will be different. This Vision will be connected to the competitive reality in a way that enables people to believe that “we” are actually in this one together. This leader will be driven by doing what is right. This leader will be able to defend the project from the torrential storm of well intentioned, risk averse managers whose often, but not always, well-meaning questions, feedback and what ifs are the kiss of death of most projects.

If you are incredibly fortunate the second Leader will be the Sustaining Leader. This is generally someone who was a part of the original design/implementation team. They were present from conception to detailed planning, from the creation of a selection process to the onboarding of chosen team members, and on through implementation to the first, second and third course corrections. They get the Vision viscerally and are passionate about the work design in a blunt and aggressive manner. They know it is the best path for the facility, the company and the workforce. They believe this, down to the bone. They may not be able to create the Vision, but they will charge hell with a bucket of ice water to try and make the transition work.

…it is generally the shop floor workforce who are the keepers of the vision.

The third Leader is an Adaptive Leader. This individual can create survival level change while cleaving unto the framework of the original Vision, and you can count on it that there will be major alterations necessary for the survival of the installed work system. They can distinguish false steps from real adaptations. They are almost able to peak around the corner to the future and boldly and accurately predict what is necessary to survive and thrive. They may or may not have been a part of the original leadership team. They will have the intestinal fortitude and political acumen necessary to shield the team from assaults based on short term changes in upper management and business conditions. Again, this is a very rare capability.

However, finding and putting in place the Adaptive Leader almost never happens. Most often the Narcissistic Leader is installed, and this is where close to 90% of all projects move from a chance for success to the failure category – hence the Three Leader Litmus Test© name. This manager did not come of age in the new system. They believe that they have a better answer, and are desperately driven to achieve and prove their merit and worth. They want badly to climb the ladder. They are often put in place at a time when Corporate has forgotten the investment in and success achieved in this experimental endeavor. This leader wants immediate movement towards their new and improved Vision, and this will kill any chance of success.

At this point it is generally the shop floor workforce who are the keepers of the Vision. They have a clear grasp of what work was – a four letter word, and what it has become for such a brief, alive moment since implementation, and what the nearly inevitable coming destruction of hope and meaningful work

will mean. They will fight to keep it alive. I have advised team members in organizational change projects to beware that if they join and discover success, and leadership cannot stay the course, then they will forever be ruined. Returning to a regressed work environment is anathema. They will have had a taste of what can be and the loss of that reality is terribly painful. The workforce, both hourly and salaried, will be horribly disillusioned, once again. Nevertheless, more often than not a significant percentage of the workforce will sign up because in their hearts they know there is a better way.

What counts as a successful change? The only metric that counts is whether it survives past the third Leader.

Therefore, the time framework in this Litmus test is very long. Five to seven years is a minimum, and more likely it will be 10 years or longer. Are you willing to pay this price? Do you have the courage to outlast the naysayers, the climbers and the egomaniacs? Do you have the patience to survive the business cycles – the flush times and the constrained cost times?

…often… a significant percentage of the workforce will sign up because in their hearts they know there is a better way.

- Absolute metric of success comparative to a situational metric.

- Transformational leadership and its scarcity, and what to do in the real world, in a real change initiative.

- What your organization is ready for “now”, not some fantasy land picture where everything works the way it is supposed to?

- If you cannot get the Leadership that you need than what do you do with what you have?

- Letting go of control, responsibility, accountability; the organizational change step that almost never happens.

- Sustainability, with a focus on internalizing the principles of the work system.

One way to define Transformational Leadership is to quote Supreme Court Justice Potter Stewart who famously said, “I know it when I see it.” This is a true statement regarding many things, including leadership. If you have known a transformational leader then “you know it when you see it.” However, it is so rare that many think they have known such leadership when in reality they have not.

“I know it when I see it.”

… it is so rare that many think they have known such leadership when in reality, they have not.

To build on Potter’s quote, Transformational Leaders do things because it is the right thing to do and coincidentally what is in the best interests of the organization. They are continually surprised by what they do not know and relish the challenge of figuring things out. They are not engineers or financial analysts or process experts, and yet they are all of these things. More importantly they intuitively excel at the people side of the equation, and yet are completely comfortable at holding people accountable for achieving the hard things. They are driven to find and build the best team, filled with people that are smarter, more accomplished, quicker and adaptable than they are. They know that such a team gets the best results and getting those results makes for better teams.

What follows are 9 lessons learned and 3 take aways regarding Change and Transformational Leadership.

Successful large scale cultural change initiatives, in a zero sum, win/lose sense, require a transformational leader. This is an obvious observation – right, but in reality, not so much.

Finding a transformational leader is almost impossible. They are just not out there. You are more likely to be struck by lightning than to find a transformational leader in your organization.

Most leaders in most organizations believe they are transformational, and most organizations believe they have such leaders. Both perceptions are dangerously warped!

If you have the great good fortune to work with a transformational leader you are incredibly fortunate. If you have this experience two or three times in your lifetime you have hit the lottery.

If you believe you have had this experience more than three times we need to have a conversation about what it means to be a transformational leader. An MBA from an elite school, a fancy title, or a big IQ does not mean you are transformational!

In a technologically driven company the reality is even bleaker. A transformational engineer is essentially an oxymoron.

On the rare occasion when you find a transformational engineer, a blend of the logical and the intuitive, the organization itself freaks out! This person is so strange, so different, other leaders just do not know how to take them. A transformational leader drives most other leaders’ nuts!

Transformational leaders just do the right thing because it is the right thing to do and, more often than not, everything works out. This drives most organizations nuts and usually the organization reacts by marginalizing, transferring, or eliminating the irritant.

Transformational leadership is a vocation, a calling, yet such leaders are completely fluent in the technical aspects of the process and the financial analytics of the business. They are trilingual. They speak the psychological, the financial and the technical. However, they viscerally understand the critical questions in cultural change initiatives are always psychological.

The following 3 Take Aways are intended to drive effort toward what will actually help in a major change initiative. One, start with the reality that you probably will not find a transformational leader. Two, you are now free to realistically pick and choose talent from what you have, not what you wish that you had. Three, the outcome is not a matter of getting the project up, on time and under budget; the important matter in today’s competitive landscape is bringing it up with an empowered workforce capable of owning the process and safely wringing every advantage possible out of it.

Take Away 1: If you cannot find a transformational leader – don’t have a panic attack. Reality bites, the truth hurts, but starting any place other than what is real is truly a bad mistake.

Take Away 2: Lack of a transformational leader is not the kiss of death and in fact can be liberating.

Take Away 3: Leaders who are principled, humane, non-linear thinkers, with thick skins and steel for a spine will do just fine!

Change Management/Personal Knowledge

In almost every job description for Change Management consultants is a statement about having a certification in one of the major Change Methodologies. This makes sense – right? But in the real world not so much.

Two of these methodologies are: Kurt Lewin’s – Unfreeze, Refreeze, Reinforcement, and Jeff Hiatt’s – Adkar. There are others. Each has merit. However, in my opinion what is critical is the ability to differentiate between real world knowledge and book world knowledge, or put another way between tacit knowledge and explicit knowledge. 1,2 From this perspective the theoretical model is of secondary importance.

Most knowledge is in some way tacit. It is not possible to write it all down. It must be experienced, absorbed through doing, trying and failing. I can write a procedure on how to ride a horse but that is not the same thing as actually being able to ride a horse. This sounds like a statement of the obvious, but in real life change projects it is literally forgotten all of the time.

Without real world, tacit knowledge of Change, any certification is of limited value. Having a certification does not mean you can answer the most important questions. I can study and discuss Kotter, Hiatt, Von Mises or Lewin. However, without tacit understanding, which only comes from experience and doing, you never grasp the chaos of change, the artistry of change, the situationally driven nature of change.

… without tacit understanding, … you never grasp the chaos of change, the artistry of change, the situationally driven nature of change.

The real world is what teaches us the painful and necessary lessons. At the core, we all know this. It is the school of hard knocks that, if listened to and grasped, makes one a valuable consultant to change projects.

Let’s look at a real-world example. Learning how to ride a horse has been the hardest sport I have ever tried to master. In dressage, the whole point is to ride so that an observer cannot even tell if the rider is doing anything at all. The reality is that the rider is always doing something. The rider is never ‘just along for the ride.’

This reminds me of what I try to do when I “consult” on major change projects. There is basically never a moment when you are not engaged with the process of change. It sometimes may be difficult for the client to see or understand what is happening, but if the consultant is effective critically important interventions, aides, cues, hints and suggestions are happening all the time.

The price you pay for making a mistake in riding also reminds me of the real world of business change. When I make a bad mistake while riding, I often end up with broken bones. Making a bad mistake in a change project often results in an equally painful event, the business equivalent of a compound fracture! The upside is that some number and breadth of such experiences make you more and more valuable as a teacher, mentor or consultant.

The canter transition is a necessary riding skill. There is a procedure, an SOP. The steps are explicit and any trainer worth their salt will tell you basically the same thing. The steps are explicit, but the actual event of the canter transition is tacit. You can

do everything exactly as you are told, over and over, again and again and still

not get it right.

It does not happen the way the explicit procedure states it will because the horse is a sentient being, with good days and bad days, as is the person. Every day the horse is different. Every day the rider is equally as different. Every day together they are different. There is a core set of steps to make a canter transition possible, but at the core, the transition is situational, on a moment by moment basis.

Sometimes the horse is right there with you and sometimes his mind is on the saber-toothed butterfly that is about to eat him. However, once a canter transition becomes personal knowledge, then you can have a conversation with your horse about all of these things, as you are riding along, that sets the stage for the transition and boom – it happens. It happens because you are intuitively, automatically taking all that stuff into account, because you know what it is supposed to feel like and when it feels right – you have the canter.

Let’s look at a real world transformational Change example. A communication plan will be a part of any Change effort. It just makes sense. If it is a good plan, it will be quite detailed. It will certainly include identification of and talking points for every critical stakeholder group. Getting this step right is incredibly important and unbelievably difficult. The communication action plan is the explicit knowledge component.

The help that is truly valuable, however, comes from the person who has experienced reality enough times to know and understand that it is impossible to plan and execute a communication strategy that works for every stakeholder group. It is just not possible. No matter what you do there will be problems. You will at best find an effective middle ground and at worst create civil war by what you do or do not do. One thing you cannot do is to create a plan that makes every stakeholder and stakeholder group contented. It just will not happen!

A simple, almost obvious explanation is that you cannot touch base with every stakeholder group simultaneously. Without the ability to talk to every group at the same time, someone or some group will be upset. Someone or some group will be second. You have to make hard choices.

Do I talk with Front Line Supervisors about the self-directed world before I talk with the work force about a self-directed world? If I talk with the Salaried group first I run the big risk of alienating the Hourly group. If I speak with the Hourly group first, I will not only alienate the Front Line Supervisors, but

will destroy any trust they may have in the change process. As well, every High Performance Work System is structured with less direct supervision. The Front Line Supervisors’ work lives are literally on the line; their ability to earn a living, support their families, take pride in what they do. It is all on the line.

Oh, and by the way this whole thing about High Performance is based on creating an operating Hourly team that trusts each other and their leadership. This team must do what is necessary because they own their process/equipment, not because they are told what to do and when to do it. From their perspective if Leaders cannot even see fit to speak with the hourly team first why should they trust anything that is said, now or in the future. Explaining, especially after the fact, to these key stakeholders why I could not find a way to talk with them first is not a good place to be.

Whose fears and concerns and uncertainties and questions do I address first? In the real world, timing is everything, but the reality is you cannot sequence the perfect plan. Do I anger one group or the other? And in the final analysis I will probably upset both – so what do I do?

…major change endeavors always happen at break neck speed

I want someone who has been there and experienced this reality, someone who tacitly knows enough to make a judgement call that maximizes the positive and minimizes the negatives. The explicit knowledge about having a communications strategy is irrelevant in comparison to the tacit knowledge of what happens when you are trying to give the right cue to go into a canter or even more importantly into a full-blown gallop, because major change endeavors always happen at break neck speed. The wrong cue at the wrong time won’t get you the canter transition, and mistakes breaks bones, destroy the Vision of a great canter transition, and ruins transformational change.

If you do not possess this tacit knowledge you cannot really help! You may know the change model, but so what. This reality is why the phrase a mile wide and an inch deep is heard so often in describing consultants. I want someone that is a mile deep. I do not need someone to tell me to put together a communication plan. I need someone who can give the best suggestions humanly possible about which stakeholder group I should talk with first, and then explore with me what to do when the proverbial stuff hits the fan, everybody’s hair is on fire, and chaos is getting the upper hand.

You cannot learn from history until you have a history.

Change is tricky, very tricky. Expert assistance is a really good idea. I started this article by asking the question: who will you call when you need help with transformational change? My answer is to build on George Santayana’s thought: “those who do not learn from history are doomed to repeat it.” The build is you cannot learn from history until you have lived and experienced large-scale change efforts. You cannot learn from history until you have a history. Find the person who has been there and done that and you just might avoid the pain of business compound fractures!

REFERENCES

1) The term “tacit knowing” or “tacit knowledge” is attributed to Michael Polanyi. Chicago: University of Chicago Press, 1958 in Personal Knowledge.

2) “In his later work The Tacit Dimension he made the assertion that “we can know more than we can tell.” He states not only that there is knowledge that cannot be adequately articulated by verbal means, but also that all knowledge is rooted in tacit knowledge. Polanyi, Michael (1966), The Tacit Dimension, University of Chicago Press: Chicago.”

Every sane organization wants to improve. However, before any improvement process begins the question that must be asked and answered is – what change are you ready for?

Every business at some point asks if there is a better, more efficient, more profitable way to do work. Once this question is asked, all sorts of odd things happen. Leadership egos run wild. There is enormous pressure to be better than the current best. If a plant is seen as better, then “we” must beat them. A competitor went self-directed? Then “we” will too. “They” did it in 36 months; “we” will do it in 12. Plant A has no front-line supervisors? Then every other plant is going to be supervisorless – right now. Woe be to the people at the tip of the spear charged with implementing the change.

Every business at some point asks if there is a better, more efficient, more profitable way to do work.

Finally, someone will ask: “how do we do this?” What usually follows is the formation of an Organizational Design team. This team is tasked with putting together an action plan, which typically includes items like benchmarking internal and external companies, defining the compelling reason for change, communication strategies, and timelines. Eventually a new work design is created, and the troops are asked to charge ahead.

Hope is not a strategy

All well and good—except that doing all of the standard, necessary, normal action plan things is not what’s needed for success. What is required is an absolutely crystal-clear picture of what is realistically possible, feasible, attainable, and sustainable.

Organizations try to learn from their mistakes, but in this arena, it never seems to happen. Work designs are too frequently based on fantasy rather than reality—on what is hoped for rather than what is feasible. When the goal is to beat all current and future competitors in the next several quarters, and the starting point is 3rd or 4th quartile, then there is a clear problem. Hope is not a strategy, but that is exactly what this gap represents.

Apply the Critical Four Tool© up front with intellectual honesty and the result is a clear picture of what you can realistically shoot for. It is accurate and relatively simple. It is not a mathematically fine-tuned precision instrument. It is a range finding tool that gives a broad stroke picture of what you are ready to do.

The Critical Four Tool examines four elements of change:

1) Leadership Capability: Looks first at the Change Leader. Facility leadership, department leadership, corporate leadership and front-line leadership are also a part of the mix.

2) Workforce Effectiveness: Focus is on hourly employees, e.g. operators, technicians, and maintenance; those who run and maintain the process.

3) Corporate Courage: Examines staff support functions that are critical to the success of any change initiative: e.g. Legal, Labor Relations, Human Resources, or EEOC/Affirmative Action.

4) Asset Reliability: Examines the impact of process and equipment variability.

Current state observations

Leadership Capabilities—Most organizations believe they have leaders that are transformational. Most high-level leaders believe they are transformational. Both beliefs are false. In reality, an organization should count its blessings if its leaders are capable and competent. Moreover, change is regularly sanctioned and led by “command-and-control” practitioners. Often, the “big change” is intended to move away from the exact behaviors that the designated change leader already models.

Assessment is anchored by the following behavioral statements:

Transformational

Enlightened Command and Control

Capable and Competent or Technically Capable but Psychologically Gapped

Punitive Command and Control

Closed Minded/Always Right

Workforce Effectiveness—Operators’ work lives are often 80 percent boredom and 20 percent insane moments during upset conditions. Operators believe they are seen as overpaid caretakers when things are running well and the scapegoat when things break down. They have been through so many change initiatives that few believe the next one is real, in their best interests, or will succeed. Those willing to engage are often very junior and risk being seen as “in bed with management” if they agree to be a part of the redesign process.

The stark reality is that most organizations have a small percentage of self-directed employees and a much higher percentage of entitlement-driven employees. Assessment is anchored by the following behavioral statements:

Self-Directed

Supervisor-Directed

Present

Entitlement Driven/Selfishly Directed

Disconnected

Corporate Courage—Finding deep field experience in these groups is difficult. Generally, staff support functions are not familiar with the profound insanity of a manufacturing operation, especially continuous 24/7 operations. Their tolerance for conflict and chaos is low—but there is no change without massive chaos and conflict.

Support staff incentives are often not aligned with work redesign goals. Their goal is to minimize risk, while work redesign is inherently high-risk. Change is so chaotic, difficult, and messy that only those with the courage to stay the course need be along for the ride. Assessment is anchored by the following behavioral statements:

Principled

Supportive

Benign neglect

Noise equals guilt

Presumed guilty

Asset Reliability—Reliable equipment makes for good employees, while unreliable equipment makes good employees bad and average employees worse. High states of reliability make operator ownership possible; low states of reliability lead to operators who do not and will not care for their equipment, quality, safety, or work. In an unreliable world expecting anything other than crises is folly.

The run-to-failure mindset generates bad behaviors in both hourly and salaried employees. Worst of all, this mindset is truly a vicious circle. Hourly and salaried operations and maintenance employees are often incentivized and recognized for their ability to fix what is broken, not to find ways to ensure that it never breaks down. If the process is stable, you can win. If the process is unstable, be very, very careful.

Assessment is anchored by the following behavioral statements:

Stable and capable

Preventive mindset

Work-arounds rule

Patch and go

Fire-fighting

The perfect alignment

What happens if you have a transformational leader, partnered with self-directed employees, assisted by courageous and principled corporate support groups, in a reliable operation?

In this scenario anything is possible and quite likely to be successful. This is a benchmark facility that has repeatedly demonstrated how it’s done, from simple to complex initiatives, from department reorganizations to whole mill transformations. This team can strike preemptively to stay ahead of the competition. Anything can be asked of this organization and this organization delivers almost all the time. Moreover, if a single initiative does not work as planned this facility understands and learns from mistakes and failures. Most organizations say this, but the reality is that most cannot do this.

If you work for 40 years you just might experience this alignment of all the necessary components for successful transformations—once!

If you work for 40 years you just might experience this alignment of all the necessary components for successful transformations – once!

What happens if you have a capable and competent leader, partnered with entitlement-driven employees, assisted by corporate groups that are afraid of too much noise in a facility that is trapped in a fire-fighting state of non-reliability?

In this scenario, jumping into the deep end of the transformational pool will almost certainly lead to drowning. If a facility’s equipment is run-to-failure, replete with work-arounds as the norm, then employees are in survival mode. Operators will have maladapted to this state. They believe that duct tape and patches instead of root cause identification and problem resolution are the way things are. The goal for operators is “butt time” more than “up time.”

If you are part of ten transformation projects in your career, you will probably bump into this (or worse) nine times!

If you do not believe you can get there alive you will never choose to start the journey.

Building a picture of what is realistically possible is hugely important. Many initiatives fail because the work design runs screaming away from reality.

The assessment power of the Critical Four Tool mitigates this problem. Having a superior work design is worse than useless if it is hopelessly unrealistic. As Ludwig von Mises discusses in his work, Human Action: A Treatise on Economics, people and organizations must believe they are capable of change, to change. If you do not believe you can get there alive you will never choose to start the journey.

Selection Processes

The Blunt Truth approach to selection is another way to actually get what you need – the right people into the right roles with the right skills. This option is focused on communicating the Blunt Truth about the new work system. The point is to paint such a clear picture that it enables every individual to sit down and really think about whether they are a fit for or want to be a part of the new work environment.

This approach is grounded in the idea that people can and will make informed, rational decisions if they have the right facts, the right information, and the right knowledge about the new work system. If people have the right data, they can make good choices. People have significant, not complete, but significant control over their future. Each individual decides to either opt in or opt out. The feeling of having control over “your” future is a big deal and creates enormous buy in from those that do opt in!

Each individual decides to either opt in or opt out. The feeling of having control over “your” future is a big deal and creates enormous buy in from those that do opt in!

You cannot truly own the equipment if you cannot decide whether or not you want to be a part of a new work system. The Blunt Truth approach is therefore as much an empowerment technique as it is a selection tool. This option models the idea that in a High-Performance Work System, individuals are expected to be decision makers and not just decision followers. Waiting for a supervisor to tell you what to do is anathema to High Performance. Any non-traditional organization wants, needs and requires independent thinkers and actors. This approach encourages employees to own their own destiny, which models what it means to own the process.

The fact that people make choices is liberating. In those cases where an individual opts out it is their choice, not some selection committee. If they opt in and then meet what are generally very few condition requirements of the new work system, they are in. They understand the reality of their future state. They walk in eyes wide open to the benefits and the risks. There is greater autonomy and greater accountability. They own not just the decisions they will make, but also the consequences of their decisions. This option models exactly what any ownership based organization wants and needs and must have to succeed – owners!

However, even though this option is straight forward, it is also very difficult to get right, as is true with everything else in major change initiatives. In fact, there are at least 12 really tricky issues that need to be addressed.

…there are at least 12 really tricky issues that need to be addressed.

The first is what is the Blunt Truth? What is the necessary information? What can be shared? What is not known? The operating workforce wants and deserves to know the answers to critical questions, e.g. what are the jobs in this new work system; what is this new work system; what will I be expected/required to do; how much money will I make, etc.

Simple, right? In the real world not so much.

The second is leadership cannot answer all of these questions in any useful detail. The work system is evolutionary. It is impossible to provide an accurate, detailed, specific answer to every one of these questions. A picture can be drawn of what we think it will be, but putting forth a detailed blue print is impossible. High Performance Work Systems operate more from guiding principles than from any set of defined rules. It is, by definition, fluid, adaptive and constantly shifting.

The third is that without an answer to these questions, it is difficult for any individual to decide what is in their best interests. If you were considering applying for or accepting a new position, you would want to know the salary, the roles and responsibilities, the general working conditions, etc. How would you feel if the answer to any of your questions is we do not know?

The fourth is the workforce has reasons for wanting concrete, stable, permanent answers. They want this because, often but not always, they do not trust current Leadership, and often but not always, there are legitimate reasons for this lack of trust.

The fifth is that Leadership usually has very real problems with flexibility rather than rules, open- endedness rather than Standard Operating Procedures, and principles rather than policy. If leaders cannot lead differently than how can operators operate differently?

The sixth is that unfortunately organizations most in need of transformation are most often deeply stuck in a command and control mind set. How can the operators own the process if leadership cannot let go, and even worse do not want to let go, or even worse are terrified of their leader’s response if they do let go?

The seventh is getting everyone on the same page about what it means to own the process, be self- directed, and function in a non-traditional work system. What leaders mean by operator ownership is often not at all what an operator’s definition of ownership is, and vice versa.

The eighth is the trap of thinking that the new work system is the end goal rather than improved productivity, safety and quality. Transformational change is not a social experiment. It is a means to an end, not the end itself.

The ninth is any group-think resulting in a belief that higher compensation is the reward for becoming a part of the new work system. Higher compensation is for improved results, improved competitiveness. Period!

The tenth is in every change endeavor, compensation trumps everything else. Employees that know they cannot succeed in any position in the new work system will self-selected in because of the money. If you think about it, you would probably do the same thing!

The eleventh is that even those that self-select out can come

back and haunt you. Buyer’s remorse, second guessing, Monday morning quarterbacking will all likely kick in.

The twelfth, and perhaps the most critical, is the effectiveness of the performance management process during and post start up. What will you do when someone is not making the grade? I guarantee you that someone will not be able to meet expectations. I guarantee you that there will be issues with both leadership and operators. At some point more training, more mentoring, more anything and everything is not enough and for the sake of the system action will be required to redress the problem.

The Blunt Truth option eliminates or avoids many of the pitfalls of other approaches. It sharply minimizes the have and have nots dilemma. It models ownership right from the starting gate. It places the core responsibility for selection right where it needs to be, in the hands of those who will be working in the new system. It saves an incredible amount of time and effort that is often fruitlessly spent in attempts to craft a perfect, multi hurdle selection process. It can often be the path that keeps the peace while setting the stage for success. The Blunt Truth option will take more time, but it will save you a host of migraine headaches.

It can often be the path that keeps the peace while setting the stage for success. The Blunt Truth option will take more time, but it will save you a host of migraine headaches.

To create a High Performance Work System, you must have a High Performance team, and if you want a High Performance work team, then you must have High Performance individuals. This is axiomatic. It is a truism. It just is.

The whole really is greater than the sum of the parts. A Work System is about the Work Team. If a High Performance Work System is the goal then you will have to have a selection process – somewhere, somehow there will be a sorting out of who goes where. This is also axiomatic. It is also a truism. It also just is.

One way to get the right mix of the right people, into the right positions, is the “Blood Oath Partnership”.

One way to get the right mix of the right people, into the right positions, is the “Blood Oath Partnership”. This is a high risk, high return option that requires an unbreakable partnership between Manufacturing, Organizational Effectiveness, Human Resources, Labor Relations and Legal. Think of Clint Eastwood and Ten Bears in the classic western The Outlaw Josey Wales. They swore a blood oath. Their pact was irrevocable. Their bond was based on deeds and not words.

A successfully designed and implemented selection process requires disparate corporate and field groups to create a partnership unlike any of these groups have ever experienced. These functions must be wedded at the hip and understand each other so well they can finish each other’s sentences. Each party must sign in blood, a sworn oath to never give up, give in, or throw anybody underneath the bus. Everyone must behave as if it is the team against everyone else and everyone else will never win.

There will be unbelievably brutal and ugly things said about Leadership.

Unless you are already a part of a mature High Performing Work System then make no mistake, there will be 800 calls to Corporate Headquarters. In a union setting there will likely be National Labor Relations Board charges filed. There will most likely be disparate impact law suits. There will be unbelievably brutal and ugly things said about Leadership. There will be unbelievably brutal and ugly things said about hourly employees that choose change and the future, and take a wild leap of faith by trusting Leadership. There will be hesitation on the part of various groups as the pressure escalates and the noise and ugliness mount. Make no mistake the noise and ugliness will happen.

A painful lesson repeatedly relearned from multiple experiences is that it is excruciatingly difficult for an organization’s Leadership to understand and believe in the reality of the noise and ugliness that will ensue. The next time I am asked about Selection Processes, I will pound on a conference room table until I have made enough of a racket to make sure that everyone knows what is in store for them as the Selection Process is designed and implemented! Do not even start to walk down this path if you are not ready, willing and able to deal with full on, in your face confrontations, arguments and fights. Your good intentions are not sufficient. Your business knowledge of the competitive landscape and what must be done to survive is not enough. Your skill at project management and engineering is literally irrelevant.

What you must have is courage!

…there are employees that make the cut and there are employees that do not.

You will have to cope with the reality that some people get into the new system and some people will not. The current cultural mindset of everyone gets a blue ribbon, that dodge ball is a dangerously competitive game, and everyone can be a part of the team does not work in creating a High Performance Work Team. The stark truth is there are employees that make the cut and there are employees that do not. This reality will test your organization in unimaginable ways, perhaps all the way to the breaking point.

Those that do not make the cut are absolutely not “bad” people. It is often the case that the transition from the old system to the new system demands that you rely on the non-selected members of the workforce. However, High Performance Work teams require very specific entrepreneurial skills and interpersonal maturity. It goes way beyond technical competency. It goes way beyond showing up for

work and “just” doing your job.

Stay the course and there is a better tomorrow. Stay the course and most people in the facility will think that for the first time in their lives leadership had the courage to do what is right and should have been doing all along. If you ask opinion leaders, they will tell you that you got it mostly right, those included and those excluded. The current workers already know who the ones that fit are. They also know who does not fit. They know because every day for months and usually years these employees have worked in close proximity with each other. They already know.

They know who has the right stuff and those who cannot make the grade. In many cases they are and have been waiting for you, Leadership, to act in what is the best interests of the business. They want you to do what you should have been doing anyways. Evaluate individual and team effectiveness, fairly, effectively and repeatedly. They may not say it out loud, but at the core they know it is in their own self- interest to be a part of a High Performance Work Team.

Most major change initiatives spend an enormous amount of time, energy and money on designing a rigorous Selection Process. It is almost self-evident that success hinges on getting the right people, with the right skills and the right virtues into the right positions.

Teams of maybe five to eight people work for 40 to 80 hours or more to design the process. In excess of $200,000 may be spent on creating an analytical skill test that is rigorous enough to set the acceptance bar very high, and is legally defensible. Scores of hours are spent on parsing out ways to evaluate any individual’s ability to effectively be a member of a team. Upwards of 12, hourly and salaried highly valued and capable employees, interview perhaps 80 potential applicants. The Human Resource group does a file review for every one of these candidates. Additionally, detailed Accomplishment Records are completed and then reviewed and evaluated by Manufacturing and Human Resources. What is the outcome? The outcome is that it almost never works right.

Teams of maybe five to eight people work for 40 to 80 hours or more to design the process. In excess of $200,000 may be spent on creating an analytical skill test that is rigorous enough to set the acceptance bar very high, and is legally defensible. Scores of hours are spent on parsing out ways to evaluate any individual’s ability to effectively be a member of a team. Upwards of 12, hourly and salaried highly valued and capable employees, interview perhaps 80 potential applicants. The Human Resource group does a file review for every one of these candidates. Additionally, detailed Accomplishment Records are completed and then reviewed and evaluated by Manufacturing and Human Resources. What is the outcome? The outcome is that it almost never works right.